Our Commitment to Sakagura Ohtemon

There are no words like “compromise” in the making of Shochu at Sakagura Ohtemon.

Our sole focus is to create delicious Shochu that brings joy to everyone who drinks it. We concentrate on “ideals, creativity, and passion,” and utilize the best “production methods and techniques” to aim for the ultimate Shochu.

There is a commonality among the various techniques and ingredients used to make shochu. As mentioned in the words of our predecessors, it is about “creating while maintaining a sense of tension and enjoying the process.” Each of us, as craftsmen, imagines the taste of “delicious” for our customers with excitement in our hearts. We believe that dedicating ourselves to the daily pursuit of making shochu, without compromise, leads to the creation of uncompromisingly excellent shochu.

There are no words like “compromise” in the making of Shochu at Sakagura Ohtemon.

Our sole focus is to create delicious Shochu that brings joy to everyone who drinks it. We concentrate on “ideals, creativity, and passion,” and utilize the best “production methods and techniques” to aim for the ultimate Shochu.

There is a commonality among the various techniques and ingredients used to make shochu. As mentioned in the words of our predecessors, it is about “creating while maintaining a sense of tension and enjoying the process.” Each of us, as craftsmen, imagines the taste of “delicious” for our customers with excitement in our hearts. We believe that dedicating ourselves to the daily pursuit of making shochu, without compromise, leads to the creation of uncompromisingly excellent shochu.

Production of Shochu

Not all domestically produced ingredients are superior in every aspect.

There are specific ingredients (such as sweet potatoes, rice, barley, etc.) that are suitable for the characteristics and flavors of the product.

It is important to identify the “essential elements” for each type of shochu to utilize the ingredients and evolve the flavor into something better.

Not all domestically produced ingredients are superior in every aspect. There are specific ingredients (such as sweet potatoes, rice, barley, etc.) that are suitable for the characteristics and flavors of the product. It is important to identify the “essential elements” for each type of shochu to utilize the ingredients and evolve the flavor into something better.

◎Sorting and cutting of potatoes

At Sakagura Ohtemon, various types of potatoes such as “Kogane Sengan” and “Beni Kotobuki” are carefully cultivated by dedicated Miyazaki farmers to serve as the raw materials for Imo Shochu. After harvest, the potatoes undergo a meticulous process of sorting and washing to prepare them for the potato cutting stage, where they will be transformed into raw materials.

◎Water ( Underground Water)

Seeking further quality water, we relocated to Kitagocho in Miyazaki Prefecture in 2005, surrounded by lush green mountains. We utilize the ideal water from the Ko-Matsuyama mountain range for our shochu production.

The philosophy behind our shochu production at Sakagura Ohtemon is that “Shochu is a product of the benefits provided by microorganisms present in Kōji and yeast.” Shochu production is not something done by humans, but rather a process where microorganisms ferment and mature on their own, with humans merely assisting the process.

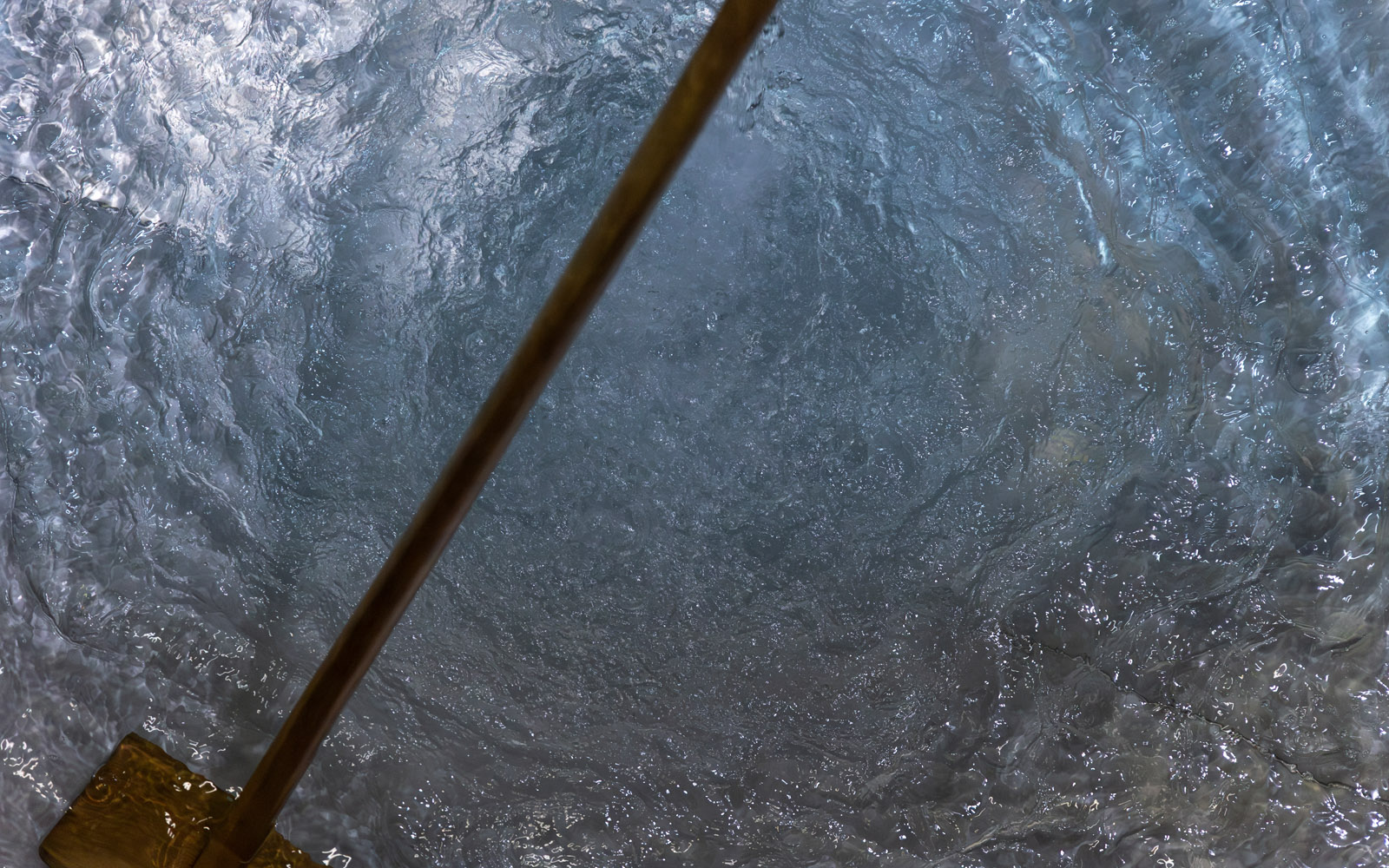

By skillfully observing the movement of microorganisms and ensuring that the Moromi (fermentation mash) is not stressed, our brewers put their heart into the process of “stirring” the moromi, resulting in a rich concentration of umami.

The philosophy behind our shochu production at Sakagura Ohtemon is that “Shochu is a product of the benefits provided by microorganisms present in Kōji and yeast.” Shochu production is not something done by humans, but rather a process where microorganisms ferment and mature on their own, with humans merely assisting the process.

By skillfully observing the movement of microorganisms and ensuring that the Moromi (fermentation mash) is not stressed, our brewers put their heart into the process of “stirring” the moromi, resulting in a rich concentration of umami.

① Koji Making Process

- The raw materials for Koji making (rice/malt) are conveyed to the mashing drum (steamer), and the process involves washing the rice, soaking, draining, steaming, and cooling.

- Once a certain temperature (specified temperature) is reached, the koji spores are sprinkled to initiate the koji fermentation process, carried out by koji molds (white/black).

- After fermenting overnight, the koji is transferred to triangular shelves to be maintained at a temperature favorable for koji mold growth.

- After approximately 30 hours, maintenance work is performed to ensure uniform temperature of the koji.

- The next morning, before the primary fermentation, additional maintenance work is done to even out the temperature of the koji and remove excess moisture through a process called “drying out.

②Primary Fermentation

- The koji is combined with water (natural underground water) and yeast (seed mash) and allowed to ferment for about 6 days to produce the primary MOROMI (fermentation mash).

③ Secondary Fermentation

- The secondary raw material (sweet potatoes) undergoes washing and sorting processes before being steamed in a potato steamer.

- The steamed secondary raw material (potatoes) is then combined with water (natural underground water) and the primary MOROMI and fermented and aged for about 10 days.

④Distillation and Storage

- After approximately 10 days of fermentation and aging, the secondary MOROMI is transferred to a still for distillation, resulting in the production of raw shochu.

- The raw shochu is filtered and then stored in tanks, jars, or barrels.

⑤Blending, Bottling, and Shipping

- The raw shochu is diluted with water (natural underground water) to adjust the alcohol content.

- During the bottling process, an inspector conducts meticulous visual inspections on each bottle.

- When packing the products in cardboard boxes, a final visual inspection is performed before shipping to customers nationwide.